Middle East

Tsurumi’s submersible explosion-proof pumps come in three series of pumps, namely, KRDX-series pumps for slurry, and HSX- and KTX-series pumps for drainage. Intended for explosion-proof applications, these pumps feature an explosion-proof structure that is suitable for drainage/pumping operations in coal mines, oil/gas refineries and similar worksites under an “explosive atmosphere” where dangerous combustible gases or vapors or flammable liquids exist.

KRDX-series pumps are submersible slurry pumps equipped with agitators recognized by both IECEx and ATEX. With the impeller, suction plate, and agitator made of high-chromium cast iron and the pump casing and motor frame made of ductile cast iron, KRDX-series pumps are excellent in terms of wear resistance, and thus suited for drainage of mud-water, sediment-containing water, and various kinds of liquid slurry. In addition, KRDX-series pumps can be built to specifications of rated voltages of 380 V to 1000 V.

HSX- and KTX-series pumps (with a motor output of up to 3.7 kW), though not complying with IECEx/ATEX, are general-purpose drainage pumps recognized by the type certification for explosion-proof-structured electric machinery by TIIS of Japan. Both single-phase HSX-series and three-phase KTX-series pumps are built to a specification requiring the use of impellers made of extremely wear-resistant high-chromium cast iron for heavy-duty workability.

These explosion-proof pumps, like Tsurumi’s other standard-specification submersible ones, are equipped with an anti-wicking cable, a motor protector, and dual inside mechanical seals with silicon carbide faces.

Tsurumi’s prime design objective is to ensure continuous duty over a long time on the basis of reliability that promises stable operation even under harsh operating environments as well as outstanding durability and maintainability.

Making the most of its longstanding experience and know-how, Tsurumi also carries products that withstand particularly severe applications such as drainage of high-temperature liquids and corrosive liquids as well as pumps built to 1000-V-rating specifications. Contact our dealer if you are interested.

Submersible Explosion-proof Dewatering Pumps Lineup

Selection Table

| Slurry | Drainage | |||

| KRDX | HSX | KTX | ||

| Discharge Bore (mm) | 80・100 | 50 | 50 - 100 | |

| Motor Output (kW) | 3.7 - 7.5 | 0.4 | 1.5 - 11 | |

| Phase | Three | Single | Three | |

| Discharge Connection | BSPT Male Threaded Coupling | Hose Coupling (Nipple type)*1 | ||

| Discharge Design | Top Discharge, Side Flow Design | Side Discharge | Top Discharge, Side Flow Design | |

| Power Cable | General*2 | NSSHÖU screened | JIS 3RNCT or JIS 3PNCT | |

| Europe | - | - | ||

| South Africa | SANS Type 41 | JIS 3RNCT | SANS Type 41 | |

| Insulation | H | E | F | |

| Applicable Voltage*2 (50Hz) V | 380 - 1000 | 110 - 240 | 380 - 525 | |

- *1 Male threaded coupling available upon request

- *2 For orders from areas other than Europe and South Africa, it is necessary to check the voltage, the cable specification, the specification of the diode and the designation of its orientation, and the circuit diagram.

Ex Certification List

| Model | International IECEx certification |

Europe ATEX certification |

Japan TIIS certification |

South Africa SANAS certification |

|

|---|---|---|---|---|---|

| KRDX | KRDX33.7-50 KRDX45.5-50 KRDX47.5-50 |

Ex d I Mb (0°C ≤ Ta ≤ +40°C) |

(0°C ≤ Ta ≤ +40°C) |

Ex d I Mb (0°C ≤ Ta ≤ +40°C) |

|

| IECEx TUR 19.0038X | TÜV 19 ATEX 8398 X | S-XPL/21.0411 X | |||

| HSX | HSX2.4S-51 | JPEx d2G4, Group II, Zone 1 (Ex d IIB T4 Gb euiv.) |

Ex db I Mb (0°C ≤ Ta ≤ +40°C) |

||

| T69055 | M-XPL/21.0678 X | ||||

| KTX | 50KTX21.5-51 | JPEx d2G4, Group II, Zone 1 (Ex d IIB T4 Gb euiv.) |

Ex db I Mb (0°C ≤ Ta ≤ +40°C) |

||

| T28999 | M-XPL/21.0678 X | ||||

| 80KTX23.7-51 | JPEx d2G4, Group II, Zone 1 (Ex d IIB T4 Gb euiv.) |

Ex db I Mb (0°C ≤ Ta ≤ +40°C) |

|||

| T29000 | M-XPL/21.0678 X | ||||

| 100KTX27.5-51 100KTX211-51 |

Ex db I Mb (0°C ≤ Ta ≤ +40°C) |

||||

| M-XPL/21.0678 X | |||||

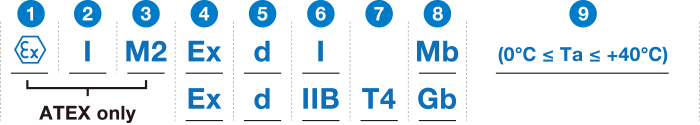

Explanation of Ex Marking

-

1ATEX symbol mark

-

2ATEX Equipment-Group

- I :

- for underground mine gas and dust

- II:

- except for underground mining, gas or dust

-

3ATEX Equipment-Category

- M1:

- for underground mine gas and dust which present over 1000h/y or >10% of the time

- M2:

- for underground mine gas and dust which present under 1000h/y or <10% of the time

- 1G, 2G, 3G:

- except for underground mining, explosive gas

- (M1>M2, 1G>2G>3G. Each higher category for higher hazard frequency covers lower.)

-

4Symbol of "Explosion Protection"

-

5Type of Protection

- d, da, db, dc:

- flameproof enclosure

- (da > d (= db) > dc. Higher grade covers lower.

"d" (= db) is for Mb and Gb of EPL.)

-

6Equipment Group

- I:

- for underground mining, mine gas and dust

- IIC, IIB, IIA:

- except for underground mining, explosive gas

- (IIC>IIB>IIA. Higher group for higher explosivity covers lower.)

-

7Temperature Class

(Max. Surface Temperature of Equipment)- T6: ≤ 85 ℃

- (acceptable gas in thermal: Carbon di-sulfide, Ethyl nitrate)

- T5: ≤ 100 ℃

- T4: ≤ 135 ℃

- (acceptable gas in thermal: All gases except Carbon di-sulfide, Ethyl nitrate)

- (T6>...>T1. Higher class for higher ignitability covers lower.)

-

8Equipment Protection Level (EPL)

- Ma:

- for underground mining, with very high protection to remain energised when mine gas is detected.

- Mb:

- for underground mining, with high protection to be de-energised when mine gas is detected.

- Ga, Gb, Gc:

- except for underground mining, explosive gas

- (Ma>Mb, Ga>Gb>Gc. Each higher protection level covers lower.)

-

9Ambient Temperature Range

- (The temperature of Ambient air and pumped liquid must be in this range.)